sourcing

With our global expertise, we map raw material flows, capabilities, and costs to identify the best factories for each project. We ensure a level playing field as we tender each project globally with detailed bill of materials.

map

At Nimble, we meticulously map and maintain a global network of manufacturers across each of our product segments. This ongoing process involves identifying, visiting, and auditing factories to ensure that we have a reliable and high-quality manufacturing base worldwide.

Our approach begins with comprehensive market research to identify potential manufacturing partners who meet our stringent quality and compliance standards. We then conduct thorough evaluations of these factories, assessing their capabilities, technological advancements, and adherence to ethical and environmental standards.

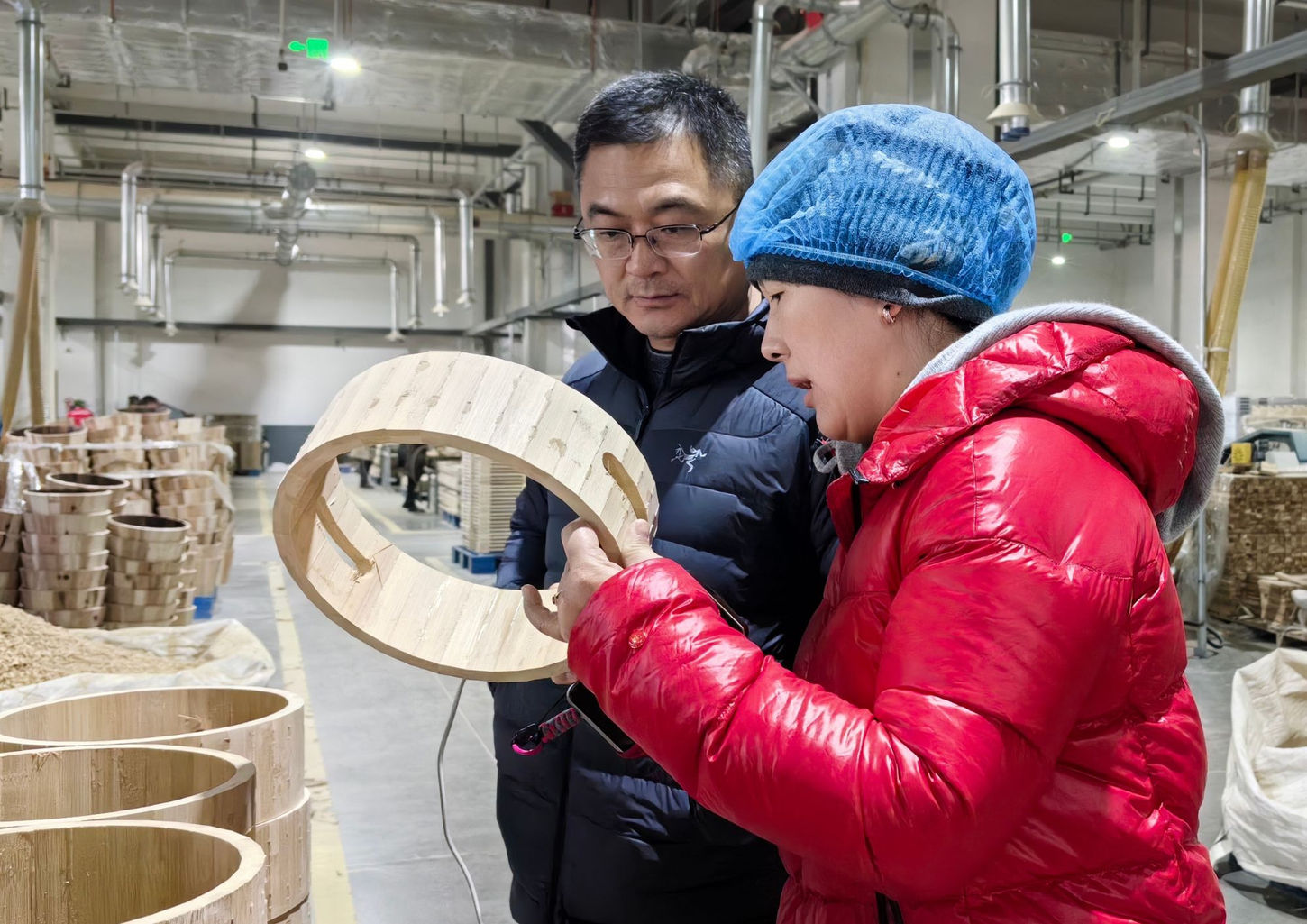

Regular visits to these facilities are integral to our process. Our teams travel to manufacturing sites to conduct on-site audits, ensuring that the factories not only meet our current standards but are also capable of continuous improvement and innovation. These audits cover all aspects of production, from raw material sourcing to final product assembly, guaranteeing consistency and excellence in every product we deliver.

By continuously mapping, visiting, and auditing our global network of manufacturers, we ensure that Nimble remains at the forefront of quality, innovation, and sustainability. This rigorous approach allows us to provide our clients with the best possible products, produced by the best possible partners, no matter where they are in the world.

audit

At Nimble, we conduct comprehensive bi-annual factory audits to ensure the highest standards of production across our manufacturing network. These audits, which typically take three days to complete, cover every aspect of the production process to guarantee safety, quality, and compliance.

During the audit, our team meticulously evaluates the factory's safety protocols, ensuring that all operations adhere to the strictest safety standards to protect workers and maintain a secure working environment. We also assess the quality management systems in place, reviewing procedures and practices to ensure consistent and superior product quality.

We inspect machinery to verify that all equipment is up-to-date, well-maintained, and capable of meeting production demands. Additionally, we scrutinize raw material and componentry sub-suppliers, ensuring that they meet our stringent quality and sustainability criteria.

Legal compliance is another critical area of our audits. We review the factory's adherence to all relevant laws and regulations, ensuring ethical and lawful operations.

By conducting these thorough bi-annual audits, Nimble ensures that every factory in our network upholds our commitment to excellence, providing our clients with the highest quality products produced in safe, compliant, and efficient environments.

factory risk assessment

At Nimble, we conduct dynamic factory risk assessments to continuously monitor and update risks based on current and past performance, factory audit scores, and the specific product types they produce for us.

Our risk assessment process begins with a thorough evaluation of each factory's performance history, including past audit scores and any incidents or issues. This historical data helps us identify patterns and potential areas of concern. We also incorporate real-time monitoring, tracking ongoing performance metrics and factory conditions to ensure we have the most up-to-date information.

Each factory's audit score plays a crucial role in our risk assessments. High-scoring factories are regularly reviewed to maintain their standards, while those with lower scores receive more frequent assessments and targeted support to address any deficiencies.

We tailor our risk assessments to the specific product types being manufactured. Different products have unique requirements and risks, so we adjust our evaluation criteria accordingly to ensure all aspects of production are covered.

By dynamically monitoring and updating risks, Nimble ensures that we proactively address potential issues, maintain high standards across our manufacturing network, and deliver consistently high-quality products to our clients.

compliance

At Nimble, we ensure stringent manufacturing compliance through a combination of our own rigorous audits and third-party inspections by reputable organizations such as Sedex and Intertek.

Our internal audit teams conduct thorough inspections of our manufacturing partners, covering every aspect of production from raw material sourcing to final product assembly. These audits ensure adherence to our strict standards for quality, safety, and sustainability.

To complement our internal efforts, we engage third-party inspection services from globally recognized organizations like Sedex and Intertek. These independent inspections provide an additional layer of scrutiny, verifying compliance with international standards and industry best practices. These third-party audits cover ethical practices, labor conditions, environmental impact, and regulatory compliance.

By integrating our own comprehensive audits with third-party inspections, Nimble ensures that all manufacturing processes meet the highest standards of compliance, providing our clients with products that are ethically produced and of superior quality.

sub sustainable practices

At Nimble, we extend our rigorous auditing processes to the sub-suppliers of the factories we partner with, ensuring quality consistency and compliance throughout the entire supply chain.

We begin by thoroughly auditing sub-suppliers, evaluating their performance, quality standards, and compliance with safety and environmental regulations. These audits are tailored to identify any risks associated with the materials and components they provide.

Based on the identified risks, we implement upstream controls to mitigate potential issues before they impact the final product. This proactive approach helps maintain the integrity of our supply chain and ensures that every component meets our high standards.

In cases where sub-suppliers do not meet our stringent requirements, we take corrective measures, including nominating alternative sub-suppliers who have been vetted and approved by our team. By carefully selecting and monitoring sub-suppliers, we ensure consistency in quality and compliance, ultimately delivering superior products to our clients.

Nimble’s commitment to comprehensive sub-supplier auditing and management guarantees that every aspect of production, from raw materials to final assembly, adheres to our exacting standards of excellence.

quality management systems

Prior to production, Nimble validates the QMS system for the production line, and manage all critical workflows to create efficient manufacturing lines.

WHAT WE CAN DO FOR YOU

Categories